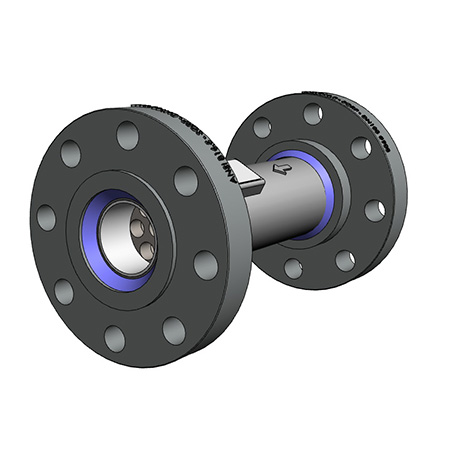

HYDROMINE™ LFC_7 Range Of Energy Dissipators

OVERVIEW

OVERVIEW

The HYDROMINE™ LFC_7 energy dissipator is a custom designed piece of equipment that reduces the upstream pressure to the designed ratio at a specific designed flow rate. The HYDROMINE™ LFC_7 energy dissipator has been developed to present a robust, simple and cost-effective method to reduce pressure at a set flow rate in open ended pipes. It will typically be used with a dam level control valve, or a column drain valve. The dissipator will ensure that the pressure is discharged from the open end at a safe pressure.

The HYDROMINE™ LFC_7 energy dissipator will increase the life of the valve upstream of it as the valve will not be required to throttle or break pressure. The high wear task is undertaken by the dissipator.

OPERATING CONDITIONS

The HYDROMINE™ LFC_7 energy dissipator have a series of orifices that break pressure and reduce flow over each stage.

NOISE LEVEL

The HYDROMINE™ LFC_7 energy dissipator is relatively quiet compared to other dissipators in the marketplace.

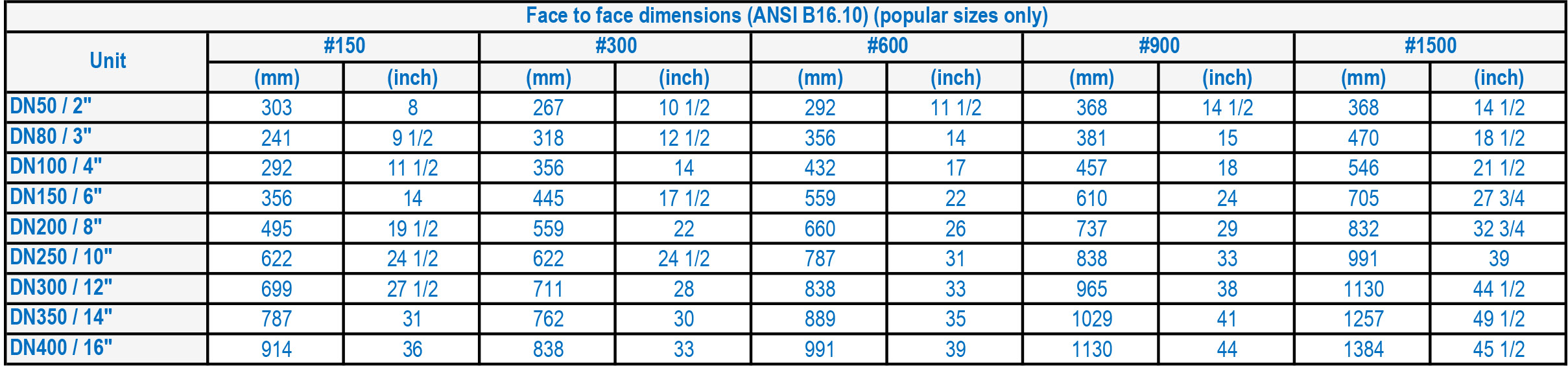

DIMENSIONS

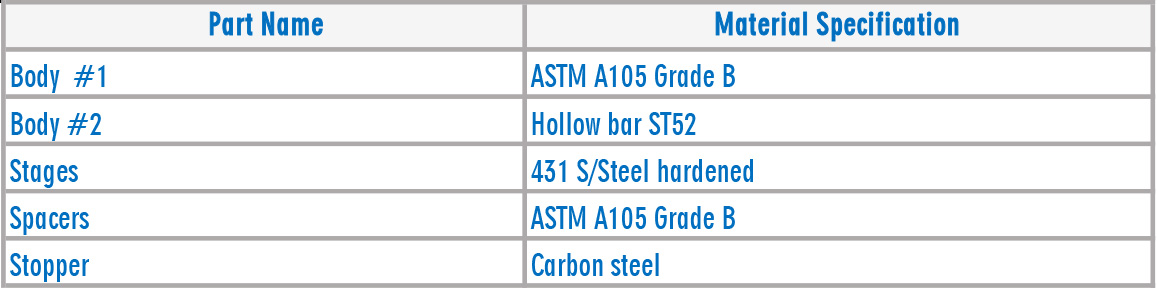

MATERIALS OF CONSTRUCTION

DESIGN AND MANUFACTURING STANDARDS

The HYDROMINE™ LFC_7 Energy Dissipator Range has been designed in accordance with various international standards as set out below:

ASME Boilers and pressure vessels design code

ANSI B16.10

API598 ANSI

B16.34 ANSI

B16.37 ANSI

B16.5 ANSI N278.1

Available sizes: DN12 / 1/2" to DN1000 / 40"

Pressure rating: up to 25MPa / 3 626 psi

Face to face dimensions: ANSI B16.10 or other as per client requirement.

Available end connections: ANSI B16.5, BS4504, BS10, AS/NZS 4331.1 (ISO 7005-1) DIN, All makes of grooved or ring joint couplings, HYDROMINE™ HMP U-Coupling, HYDROMINE™ HMP_TE tapered couplings and other as per clients requirement.

DOWNLOADS