HYDROMINE™ HMP Range of Hydraulic Pipe Couplings

OVERVIEW

OVERVIEW

The HYDROMINE™ HMP Hydraulic coupling is designed as an easy method of joining plain ended pipes in a vertical shaft. The coupling allows for expansion and contraction. It eliminates the expensive welding process, saves space and drastically reduces installation time.

The HYDROMINE™ HMP Hydraulic coupling can only be installed in a system where each pipe is supported. The top and bottom pipes in the shaft must be properly anchored. The coupling allows for expansion and contraction and no other expansion joints will be required. All pipe ends must be properly prepared for the installation and must be free of scratches, dents or any damage. If the pipe ends are well prepared, and the coupling is installed as per the installation procedure, the chances of leaks are drastically reduced.

DESIGNED GAP

There should be a gap between the pipes when they are installed in the shaft. This gap will allow for expansion, contraction of the pipe and the centre bolts / pins of the HYDROMINE™ HMP Hydraulic coupling. In most cases the design gap will be 25mm / 0,98". The design gap must be calculated and specified by the engineer, who oversees the design of the entire piping system. Should the design gap be greater than 25mm / 0,98", the face to face of the coupling will be greater than in the specified table below.

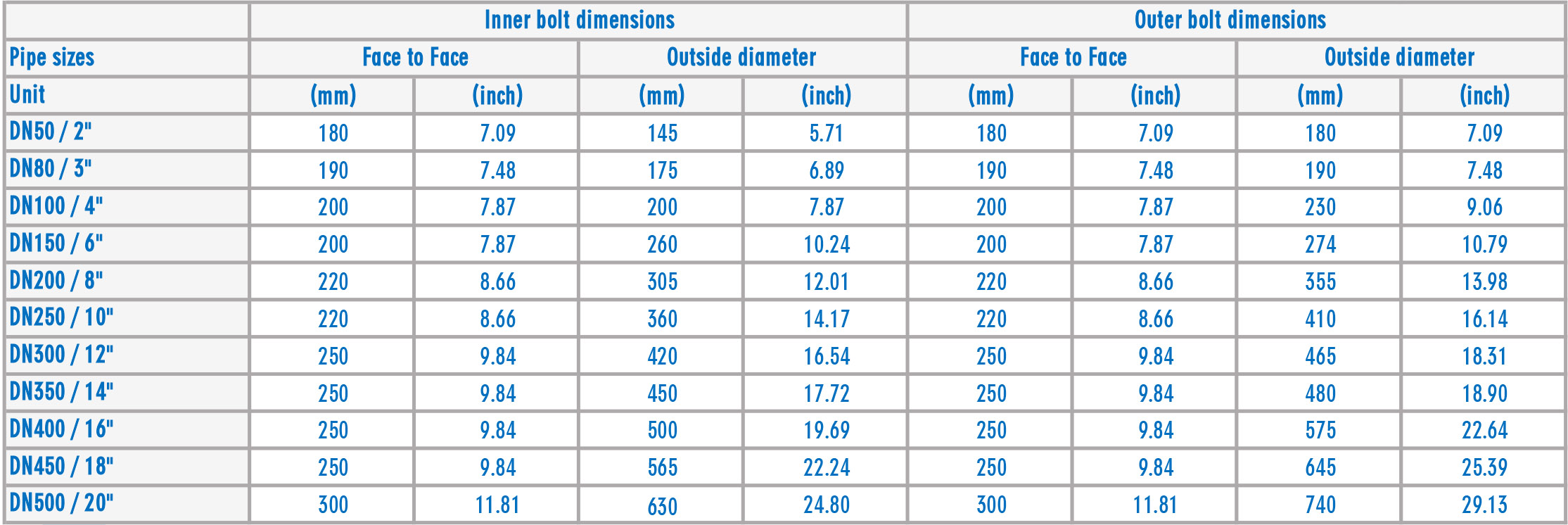

DIMENSIONS

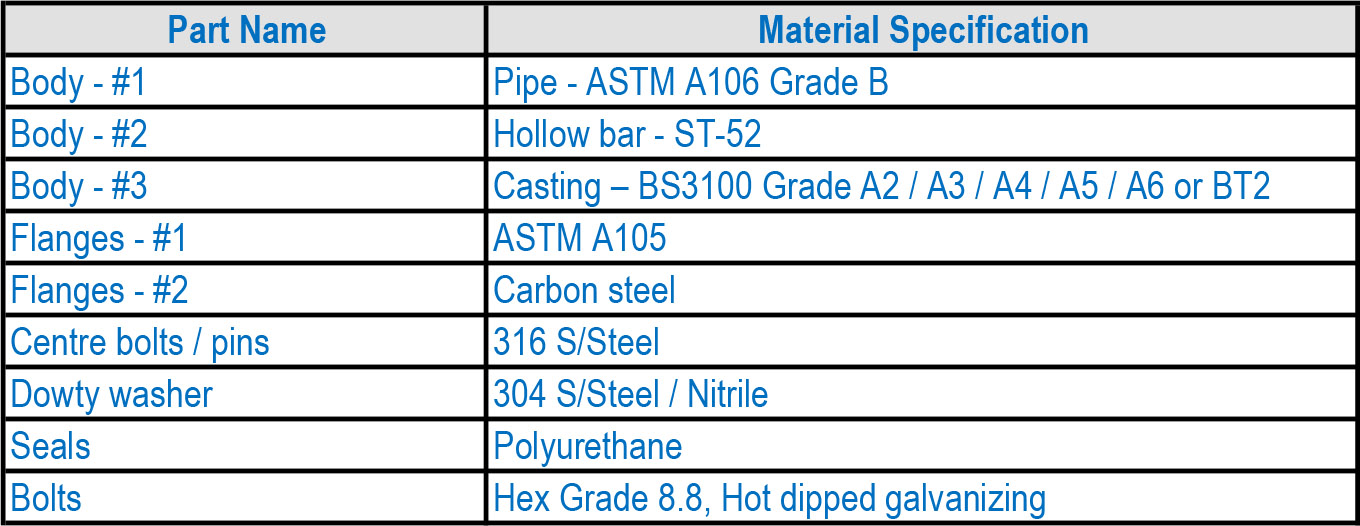

MATERIALS OF CONSTRUCTION

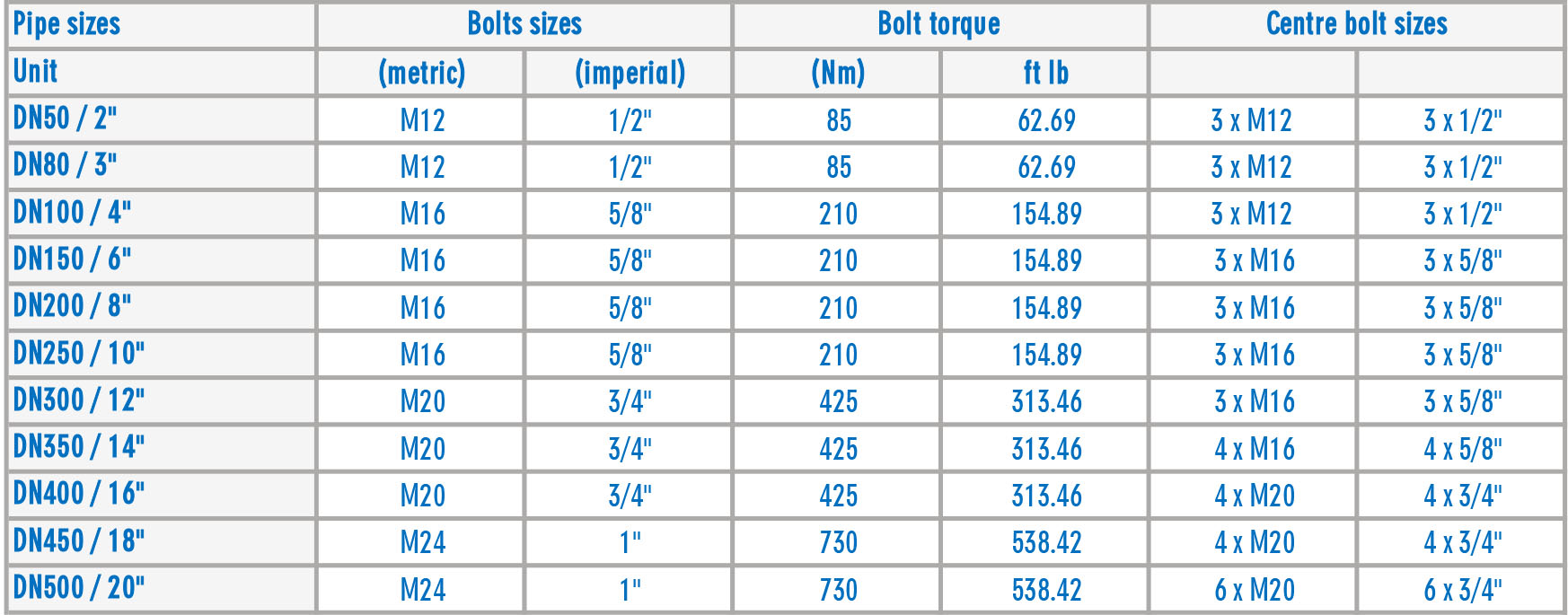

BOLT DIMENSIONS & TORQUE SETTINGS

DESIGN AND MANUFACTURING STANDARDS

The HYDROMINE™ HMP Hydraulic coupling are designed in accordance with various international standards as set out below:

ASME Boilers and pressure vessels design code

ANSI B16.34

ANSI B16.37

ANSI B31.3

Available sizes: DN50 / 2" to DN500 / 16"

Pressure rating: up to 25MPa / 3 626 psi

DOWNLOADS

COUPLING INSTALLATION