Pump Station Valve Automation

Our valves provide simple automation by:

- Starting the pump automatically on closed valve and then opening the valve under a controlled condition.

In many large pumping plants it is normal procedure to start a pump against a closed discharge valve. Once the pump is up to full speed the valve is opened slowly, flow is initiated, and then increases to its maximum as the valve continues to open. This procedure is reversed when a pump is stopped. Starting and stopping against a valve that is opened or closed slowly will prohibit the initiation of water hammer or reduce its effect to a, virtually, immeasurable quantity. Depending upon the installation the discharge valve may be operated manually or by some automatic mechanism. - Preventing the pump from running against a closed discharge valve.

- Preventing pump surge conditions.

- Stopping the pump automatically on a closed valve.

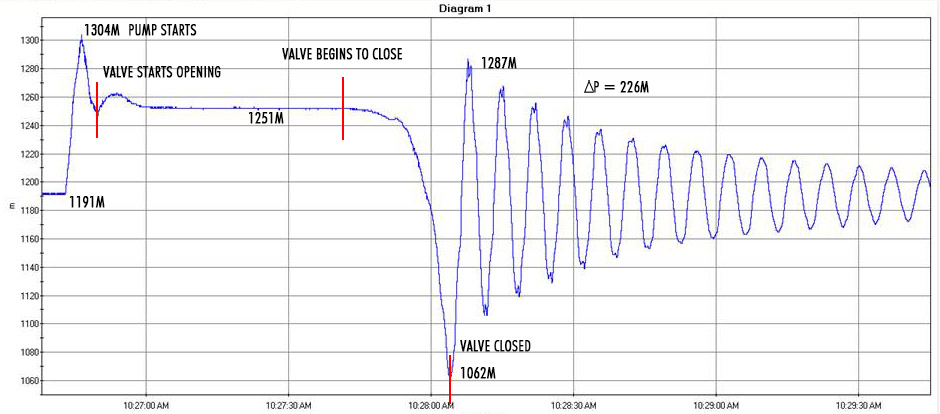

In the graph below it clearly shows a pump station in a deep mine with 1191m static head, when the pump are being started against a closed HYDROMINE™ LFC_1B discharge valve and stopped once the HYDROMINE™ LFC_1B discharge valve has reached a fully closed position. No water hammer is observed.

- Preventing and minimizing water hammer occurrences.

- Assisting and backing up the non-return valve with the pump's discharge.

- Prolonging the balancing disc life by maintaining a positive discharge pressure.

- Manual valves pose few problems if the humans who control them are in control of their actions.

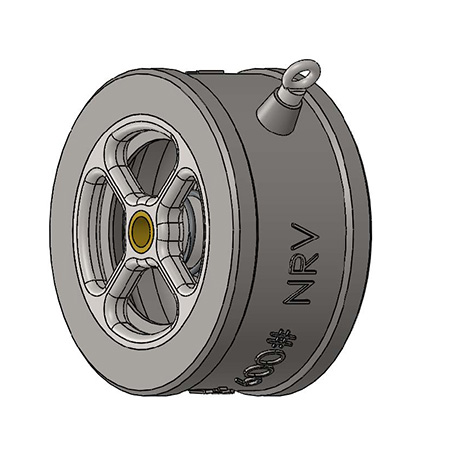

HYDROMINE™ LFC_1B Electrically Actuated Isolation Valve

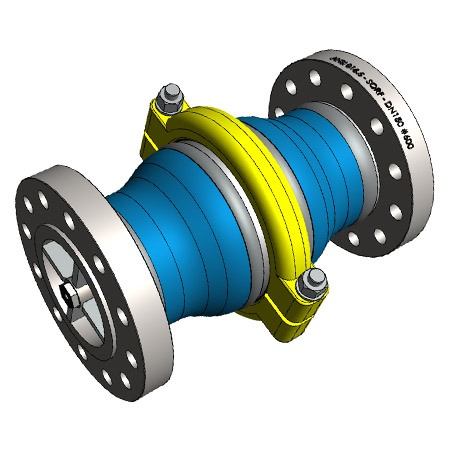

HYDROMINE™ HMP_6A Range Of Surge Reduction Check Valve

OR

SIMPLE AUTOMATION

Our valve range offers automation of the pump station through the use of small actuators. There is no need for large external actuators, pilots, controllers or other sophisticated instruments.