HYDROMINE™ LFC_3B Fail-To-Close Pneumatic Actuated Valve

The HYDROMINE™ LFC_3B Fail-to-close pneumatic actuated valve is designed to be a cost effective solution for remote isolation, level control, pump discharge control valves, and similar functions found in a pipe system. The fail-to-close function helps to protect other equipment in the system, and assists to prevent overflowing of the dams during power, air or gas failures.

Opening and closing of the valve is relatively simple. It uses a 24 VDC / 110 VAC / 220 VAC solenoid valve which is assisted by pneumatic or gas pressure ranging between 2 to 8 bar / 29 to 116 psi to open, and it uses the force generated by a spring to close. The speed of the valve can be adjusted to any desired speed fairly quickly and easily.

The benefit of using a pneumatic actuated valve system supersedes the need for similar actuation methods that are costly and unreliable, resulting in lower operating costs, better productivity, and long term sustainability.

The HYDROMINE™ LFC_3B Fail-to-close pneumatic actuated valve has been developed to present a robust, simple and cost effective (up to 2.5 MPa / 363 psi) solution to fluid handling issues in any industrial sector.

LOW OPERATING TORQUE

The HYDROMINE™ LFC_3B Fail-to-close pneumatic actuated valve is hydrostatically balanced to enable easy opening and closing at any pressure and differential conditions. It does not require the use of actuators of any kind or size.

OPERATING CONDITIONS

These HYDROMINE™ LFC_3B Fail-to-close pneumatic actuated valves are designed to operate in systems with relatively clean media like water or other liquids with a low percentage of suspended solids and chlorides . The valve's operating pH range is 2 -14 pH.

SIMPLICITY

The HYDROMINE™ LFC_3B Fail-to-close pneumatic actuated valve is designed with only one moving part called the plug assembly, thereby minimizing the effects of multiple wearing parts. The plug assembly is a piston type arrangement that is engineered to be balanced, which uses pneumatic pressure acting in a cylinder mounted on top of the valve to function. The pneumatic cylinder is designed to overcome the water pressure inside the piping system, the valve, as well as the spring. As such, only the valve own operating torque is required to overcome the sum of the friction forces generated within the valve body, the seals, the cylinder, the weight of the plug (depending on the installation configuration) and the tension of the spring.

The torque requirement is not affected by inline pressure variants and therefore makes the valve extremely reliable for actuation applications. The pneumatic actuation cylinder is simple in comparison to an electric actuator. The HYDROMINE™ LFC_3B Fail-to-close pneumatic actuated valve can easily be fitted with limit switches to give open and closed indications.

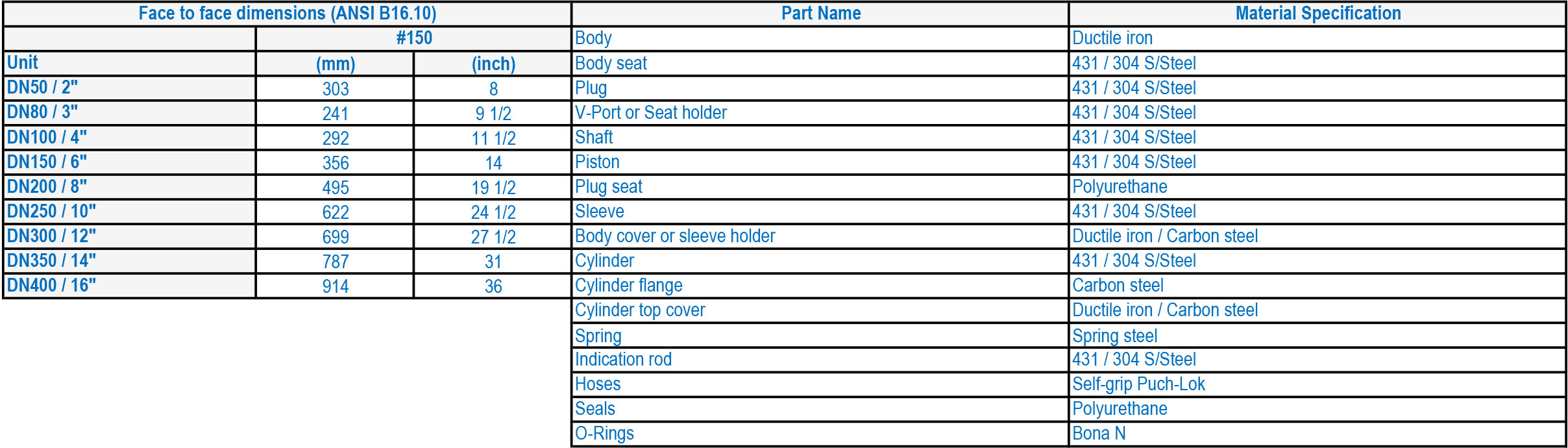

MATERIALS & DIMENSIONS

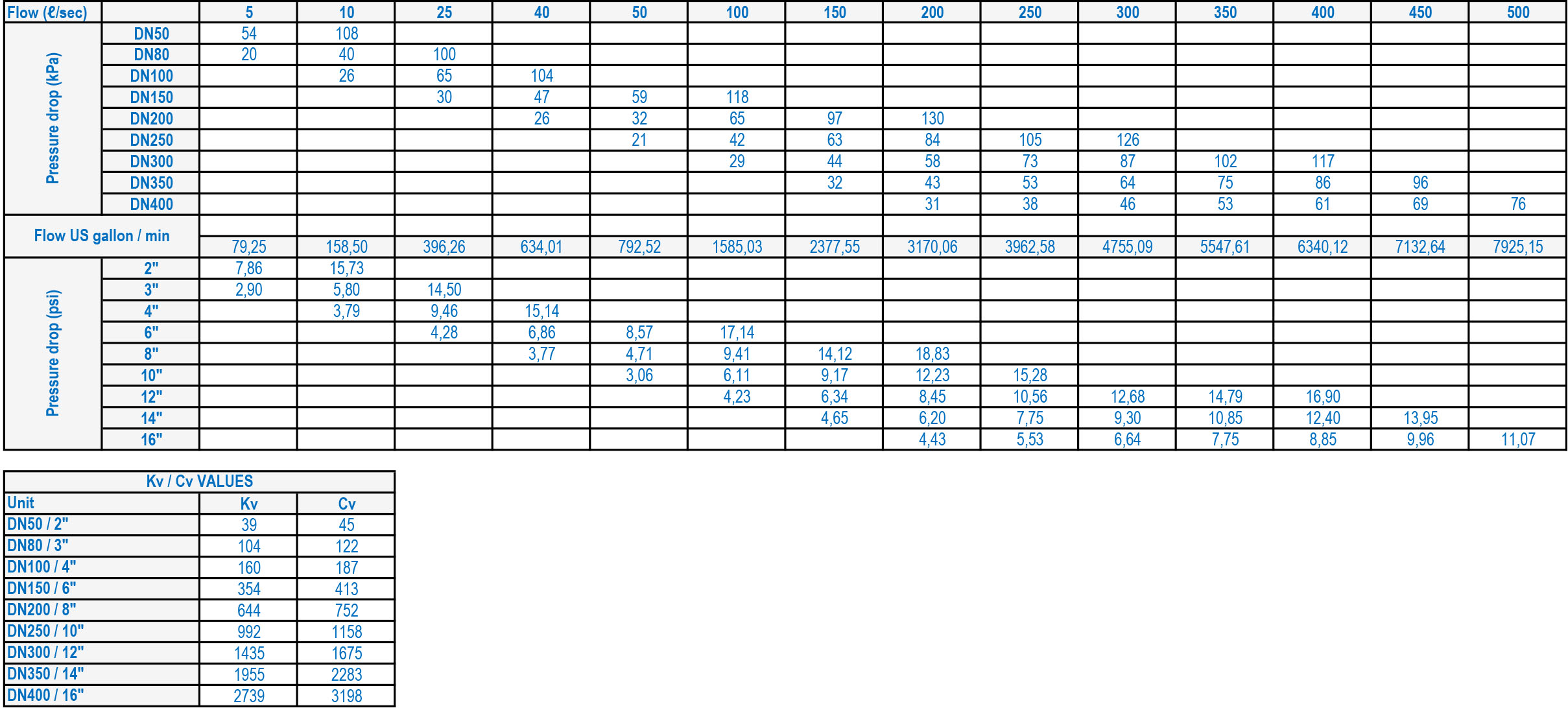

FLOW RATES

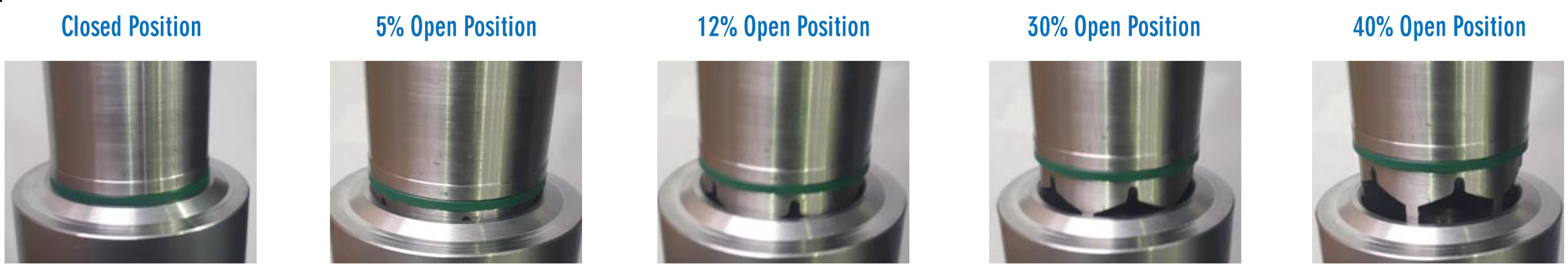

PLUG ASSEMBLY, V-PORT AND DEALING WITH CAVITATION

As displayed, the HYDROMINE™ LFC_3B Fail-To-Close Pneumatic Actuated Valve plug assembly and movements.

Closed Position: Shows the plug assembly on the body seat in a fully closed valve position.

5% Open Position: Shows the plug assemble in a 5% open position. It can clearly be seen that only the top of the V-Port opens and creates a flow path. This reduces cavitation and helps with fine control at low flow conditions.

12% Open Position: Shows the plug assembly in the 12% open position. Now it can be observed how the V-Port moved away from the seat and the openings are increasing proportionally. At this point the top of the V-Ports is now being exposed to the flow path.

30% Open Position: Shows the plug assembly in the 30% opened position. Now it can clearly be seen that the full V-Port is creating a larger orifice in the flow path. Up to this point, cavitation needs to be dealt with to increase the life expectancy of the valve. The V-port trim ensures that the seating elements are further apart from each other during low flow allowing the cavitation to take place on noncritical components of the valve.

40% Open Position: Shows the plug assembly in the 40% open position. Now it can clearly be seen that the V-Port is completely away from the seat and the flow path is now relatively large. At this point the flow is approaching its medium demand flow rate and the V-Port has little to no function.

VALVE SIZING

Please consult with a technical expert at HYDROMINE™ for clarification on correct valve sizing on your specific requirements.

LOW MAINTENANCE REQUIREMENT

The HYDROMINE™ LFC_3B Fail-to-close pneumatic actuated valve requires minimal maintenance, the majority of which can be conducted with the valve remaining in situ. All moving parts are manufactured from stainless steel which increases their reliability and durability.

DESIGN AND MANUFACTURING STANDARDS

The HYDROMINE™ LFC_3B Fail-to-close pneumatic actuated valve is designed in accordance with various International Boiler and Pressure vessel standards, as set out below:

ASME Boilers and pressure vessels design code

ANSI B16.10

API598

ANSI B16.34

ANSI B16.37

ANSI B16.5

ANSI N278 .1

Available sizes: DN50 / 2" to DN400 / 16"

Pressure rating: up to 2.5 MPa / 363 psi

Available end connections: ANSI Bl 6.5, BS4504, BS10, AS/NZS 4331.1 (ISO 7005-1) DIN, All makes of grooved and ring joint couplings, and as per client specific requirements.

DOWNLOADS