Business Opportunity To Become A Distributor Of The LFC™_3B PN25 Control And Safety Valve Range

The HYDROMINE GROUP of COMPANIES is looking for local business in South Africa and Africa that can become distributers in local towns or cities of the LFC™_3B PN25 Control and Safety valve range, to market and supply to the local industries. Please contact ![]() to enquire.

to enquire.

THE DISTRIBUTION PROCESS WILL BE AS FOLLOWS:

Any engineering or marketing busines with technical expertise, can apply to the Hydromine Group to become a distributor of the LFC™_3B product range within the territory where it is already operating. Examples of the target markets will include mining, agricultural, local government, industrial plants or other industries that may have a need for the LFC™_3B valve range. Businesses that are already in valve or pipes sales, installations and maintenance contractors will get first preference. The business will have to provide proof that they are already active in the specific territory that they are applying distributorship. Once the application is approved, the Hydromine Group will negotiate suitable terms and conditions. All appointments will be subjected to the conditions that the necessary Non disclosure, Confidentiality and Distribution Agreement are signed between the parties.

History of the Hydromine Group of Companies and the development of the LFC™_3B PN25 Control and Safety valve range.

The Hydromine Group of companies started operating in 1994, as a supplier of medium to high pressure isolation and control valves in the deep mining industry. From 2009 it became a manufacturer and started developing it's own ranges of valves.

The Hydromine Group of companies recognized the need for a low pressure control valve range. It then started research and developing of it's own low pressure control valve range around 2016. The LFC™_3B Control valve range were launched onto the market towards the end of 2019. From the start the LFC™_3B range have been performing very successful in all the application it have been installed.

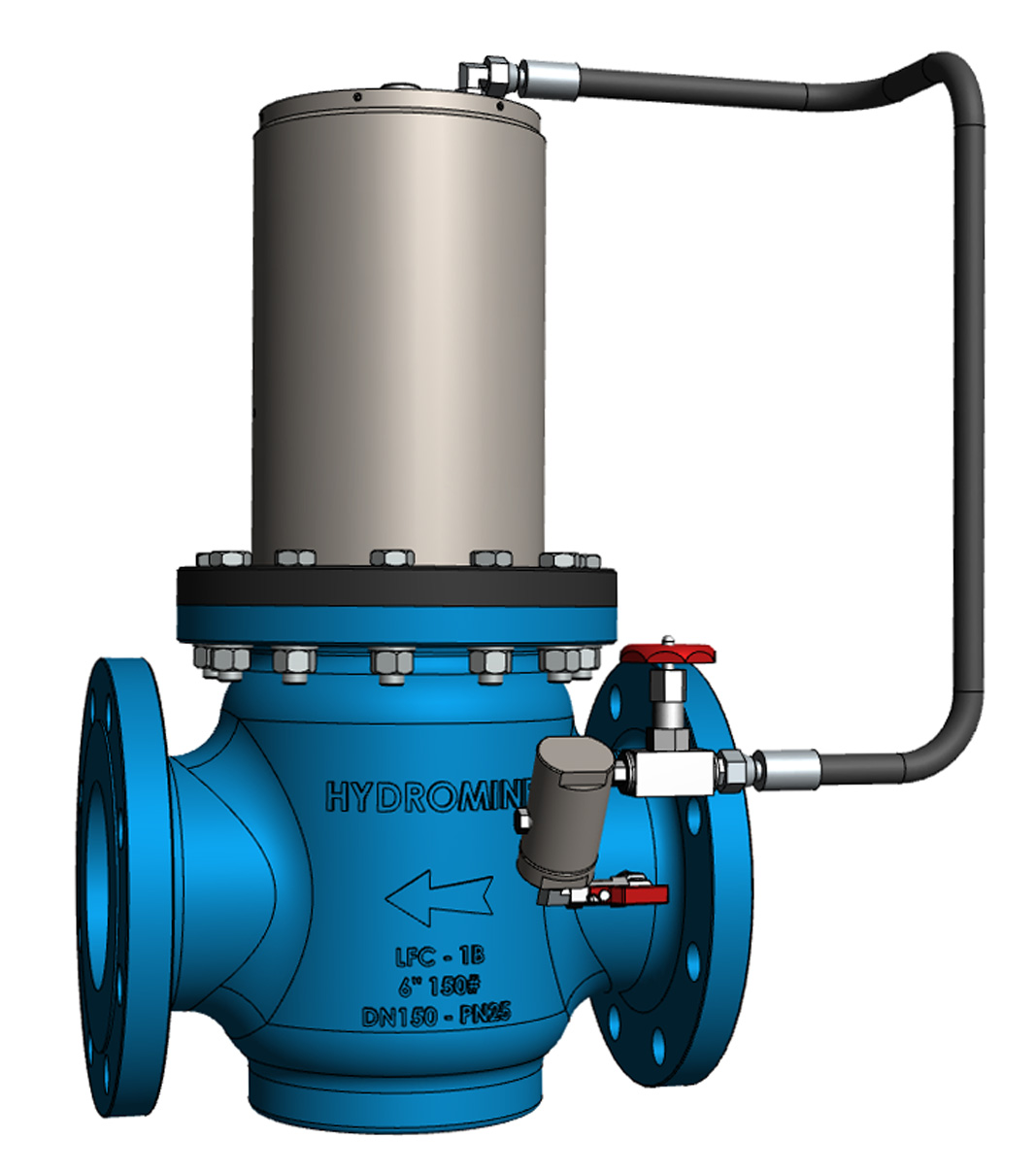

The LFC_3B design comes from the same concept as the LFC_1B medium to high pressure valve range. The LFC_3B body is designed for a maximum pressure rating of 2.5 MPa / 362 psi. It has been developed to present a robust, simple and cost-effective low pressure solution to fluid handling issues in any industrial sector.

The valve can be supplied with un-drilled flanges, that can be drilled to most flange tables such as ANSI B16.1, B16.5, BS4504, BS10, AS/NZS 4331.1 (ISO 7005-1), DIN, JIS and SANS 1123 at a maximum pressure rating of 2.5 MPa / 362 psi. The valve range is also available with Victaulic or other makes of grooved ends.

The valve range offers a wide range of applications like pressure control, flow control, surge relief, electrical actuation and pneumatic actuation with smart positioner.

LFC™_3B Control Valve Range

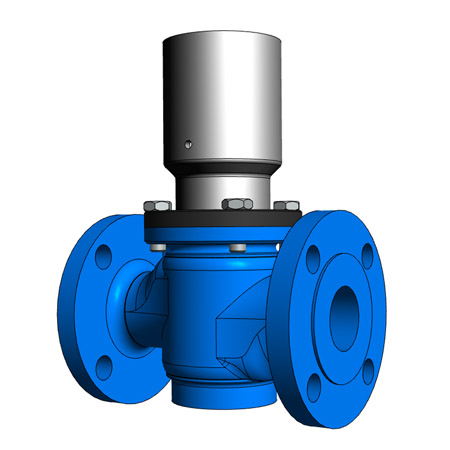

LFC™_3B PRESSURE REGULATING VALVES (FIXED RATIO VALVE):

A pressure regulating valve is designed to maintain a desired downstream pressure irrespective of the flow requirement with a fixed upstream pressure. It is very simple as it need no external actuator or pilot to operate.

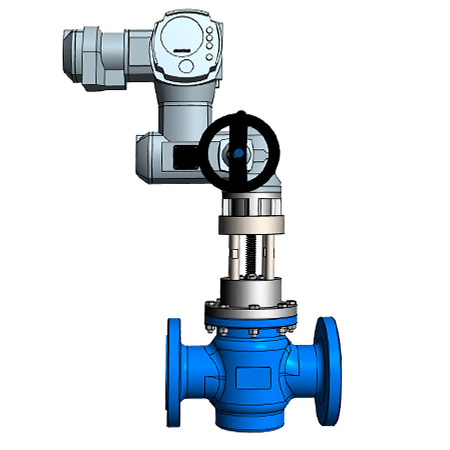

LFC™_3B PRESSURE CONTROL VALVES:

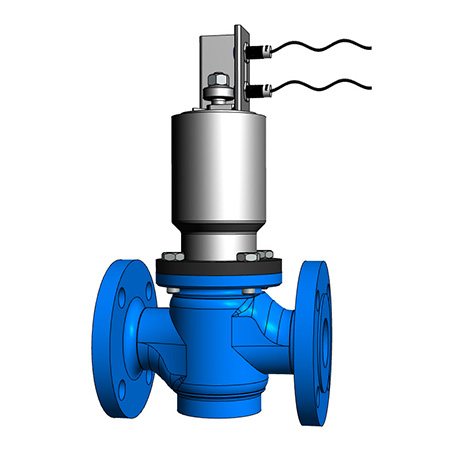

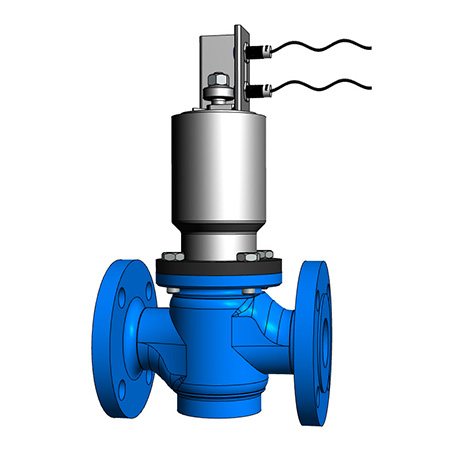

A pressure control valve is designed to maintain a desired downstream pressure irrespective of the flow requirement. The LFC™_3B pressure control valve is fitted with a modulating intelligent electrical actuator. Any make of electrical actuator can be fitted to the pressure control valve.

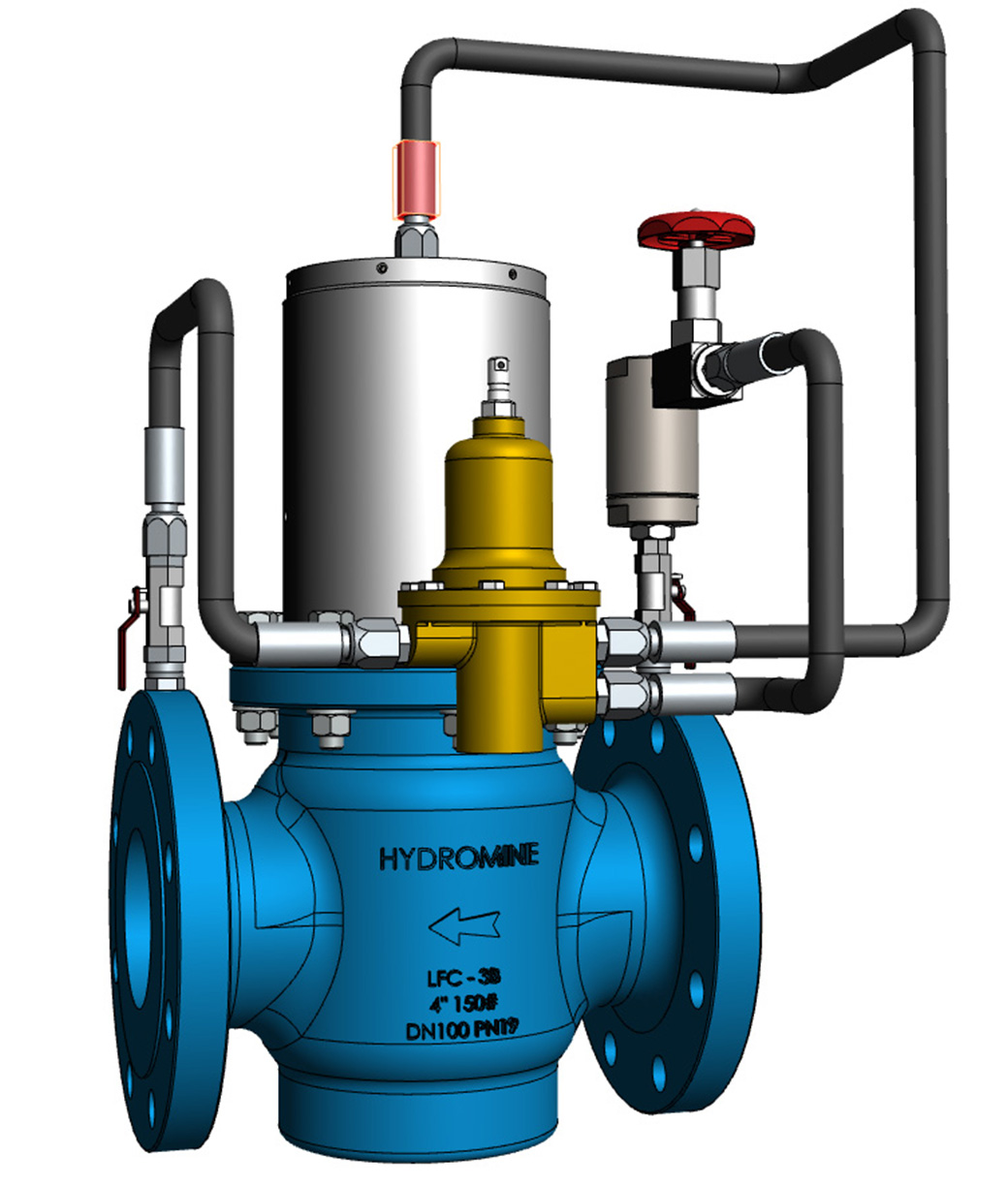

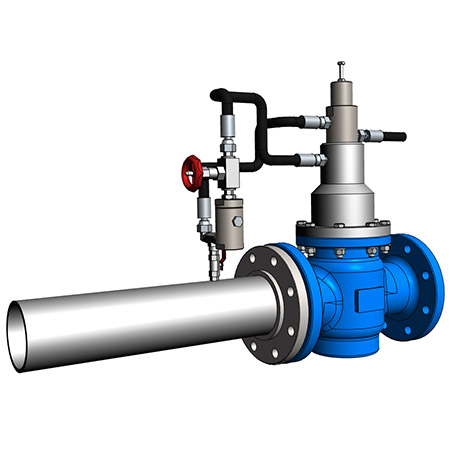

LFC™_3B PILOT OPERATED PRESSURE REGULATING VALVE:

A pressure regulating valve is designed to maintain a desired downstream pressure irrespective of the flow requirement with a variable upstream pressure.

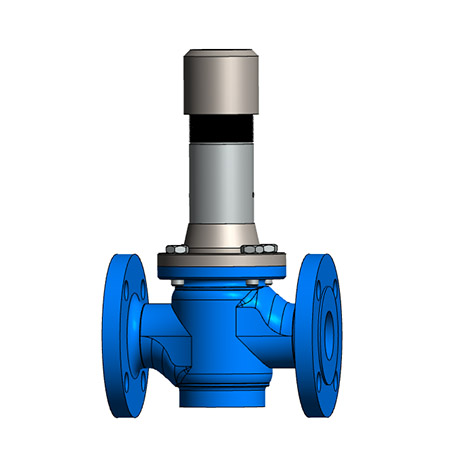

LFC™_3B SPRING ACTING SURGE RELIEF VALVES:

A surge relief valve is designed to open when a over pressure situation occurs and thereby prevent excessively high pressures from putting people and equipment at risk. The LFC™_3B Spring Acting Surge Relief Valve is the most simplest and maintenance free in that range, as it only have two moving parts, the plug assembly and the spring. The Spring tension is pre-set in the factory to the required relief pressure.

LFC™_3B PILOT OPERATED SURGE RELIEF VALVES:

A surge relief valve is designed to open when a over pressure situation occurs and thereby prevent excessively high pressures from putting people and equipment at risk. The LFC™_3B Pilot Operated Surge Relief Valves are designed, that pressure relief set point can easily be adjusted on site. The relief set point for this particular surge relief valve are very accurate and a very precise set point can be achieved.

LFC™_3B SURGE PREVENTION VALVE:

The LFC™_3B Surge prevention system is designed to prevent water hammer or pressure surges in pumping systems. Especially in mining applications. Water hammer (or, more generally, fluid hammer) is a pressure surge or wave resulting when a fluid in motion is forced to stop or change direction suddenly (Momentum Change). Water hammer commonly occurs when a pump is stopped suddenly and a pressure wave propagates in the pipe. It is a force that can arise in any pumping system that undergoes abrupt changes in its rate of flow. These flow changes can result from pump starts and stops, the opening and closing of valves, and water column separation and closure. The piping design does have an effect upon water hammer but, we have identified the main conditions resulting in hammer.

LFC™_3B WATER HYDRAULIC ACTUATED VALVES:

The LFC™_3B Water hydraulic actuated isolation valves is based on the same design as the LFC™_3B pressure regulating valve. Water hydraulic actuated valves are more cost effective than the LFC™_3B electrical actuated valves. The upstream water hydraulic power are used to actuate the LFC™_3B isolation valve. The speed of the valve can be adjusted to any desired speed fairly quickly and easily. The LFC™_3B Water hydraulic actuated isolation valve are generally used for remote isolation, level control or pump discharge control valves. Using line fluids removes the need for any gearboxes, electrical actuators or handwheels which makes them ideal for applications where tampering is a problem.

LFC™_3B PNEUMATIC ACTUATED VALVES WITH OR WITHOUT SMART POSITIONERS:

The LFC™_3B Pneumatic actuated isolation valves is based on the same design as the LFC™_3B pressure regulating valve. Pneumatic actuated valves are more cost effective than the LFC™_3B electrical actuated valves. Pneumatic pressure are used to actuate the LFC™_3B control or isolation valve. The speed of the valve can be adjusted to any desired speed fairly quickly and easily. The LFC™_3B Pneumatic actuated isolation valve are generally used for remote isolation, level control or pump discharge control valves. The LFC™_3B Pneumatic actuated valve can be fitted with a smart positioner and can be used as a pressure or flow control valve.

OPERATING CONDITIONS:

These valves are designed to operate in systems with relatively clean media like water or other liquids with a low percentage of suspended solids and chlorides. The valve's operating pH range is 2 - 14 pH.

LOW MAINTENANCE REQUIREMENT:

The LFC ™_3B valve range requires minimal maintenance, the majority of which, can be conducted with the valve remaining in situ. All LFC ™_3B Control valves are fitted with a V-Port for fine control as well as prevent cavitation at low flow.

MATERIALS OF CONSTRUCTION & DIMENSIONS:

The LFC™_3B valve range body and covers are casted from ductile iron. All the moving parts, seat and V-Port are manufactured from stainless steel which increases reliability and durability. The fact to face dimensions are in accordance with ANSI B16.10 Class 150. Clients can choose if they want the valves with undrilled flanges, drilled flanges or Victaulic grooved. Flanges can be drilled to one of the below standards:

ANSI B16.1 Class 125

ANSI B16.5 Class 150

AS/NZS 4331.1 (ISO 7005-1) Table 10 or 16

BS4504 / DIN Table 10, 16 or 25

BS10 / AS2129 Table E or F

JIS B2239 5K or 10K

SANS 1123 Table 1000, 1600 or 2500

DESIGN STANDARDS:

The LFC™_3B valve range are designed in accordance with various international standards as set out below:

ASME Boilers and pressure vessels design code

ANSI B16.10 ANSI B16.3

ANSI B16.34 ANSI B16.37

ANSI B16.5 ANSI N278.1

Available sizes: DN50 / 2" to DN400 / 16"

Pressure rating: up to 2,5MPa / 363 psi