HYDROMINE™ LFC_1B Nitrogen Acting Surge Relief Valves

OVERVIEW

OVERVIEW

A surge relief valve is designed to open when an over pressure situation occurs and thereby prevent excessively high pressures from putting people and equipment at risk. The HYDROMINE™ LFC_1B nitrogen acting surge relief valve has been developed to present a robust and simple solution to fluid handling issues in the mining and other industrial sectors.

SIMPLICITY

The HYDROMINE™ LFC_1B nitrogen acting surge relief valve is designed to minimize wearing parts and in effect only has one moving part called the plug assembly. The plug assembly is a piston that is engineered to be unbalanced. The unbalanced plug assembly together with the nitrogen pressure on top of the plug assembly, are designed to use inline fluid pressure to create specific conditions in the system without the use of an external controller or pilot. A fixed opening force can be established by fixing the surface area ratio exposed to the upstream pressure and the nitrogen pressure combined. Upstream pressure (Pu) would act to open the valve. As the Pu increases, the opening force increases proportionally causing the nitrogen to compress and the valve to open. If Pu is reduced, the valve will close proportionally in an effort to maintain its hydraulic ratio and nitrogen force combined.

VALVE SIZING

Please consult with Hydromine™ for clarification of correct sizing for your requirements.

LOW MAINTENANCE REQUIREMENT

All the moving parts of HYDROMINE™ LFC_1B nitrogen acting surge relief valve are manufactured from stainless steel which increases reliability and durability. The HYDROMINE™ LFC_1B requires minimal maintenance, the majority of which, can be conducted with the valve remaining in situ.

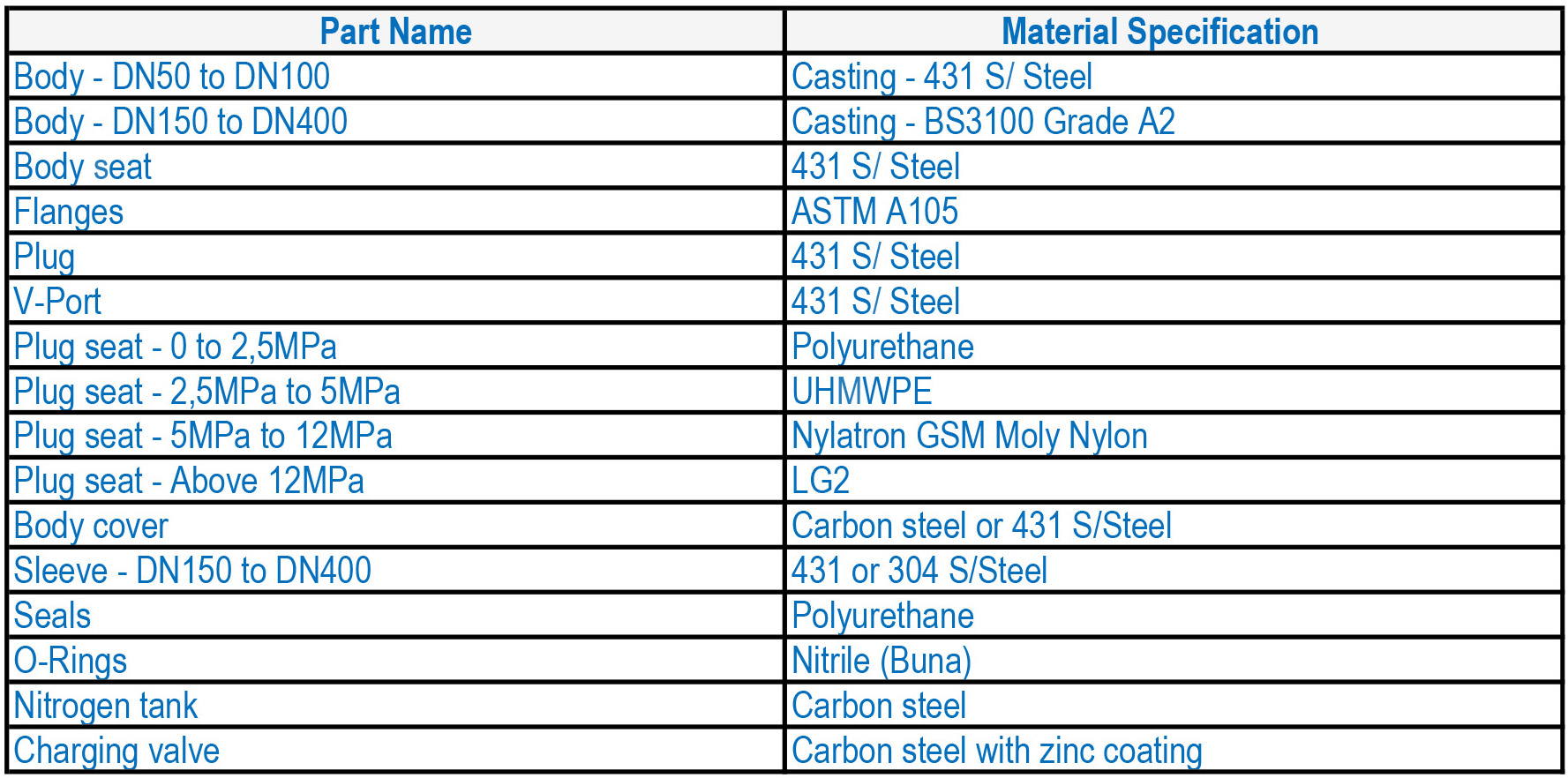

MATERIALS OF CONSTRUCTION

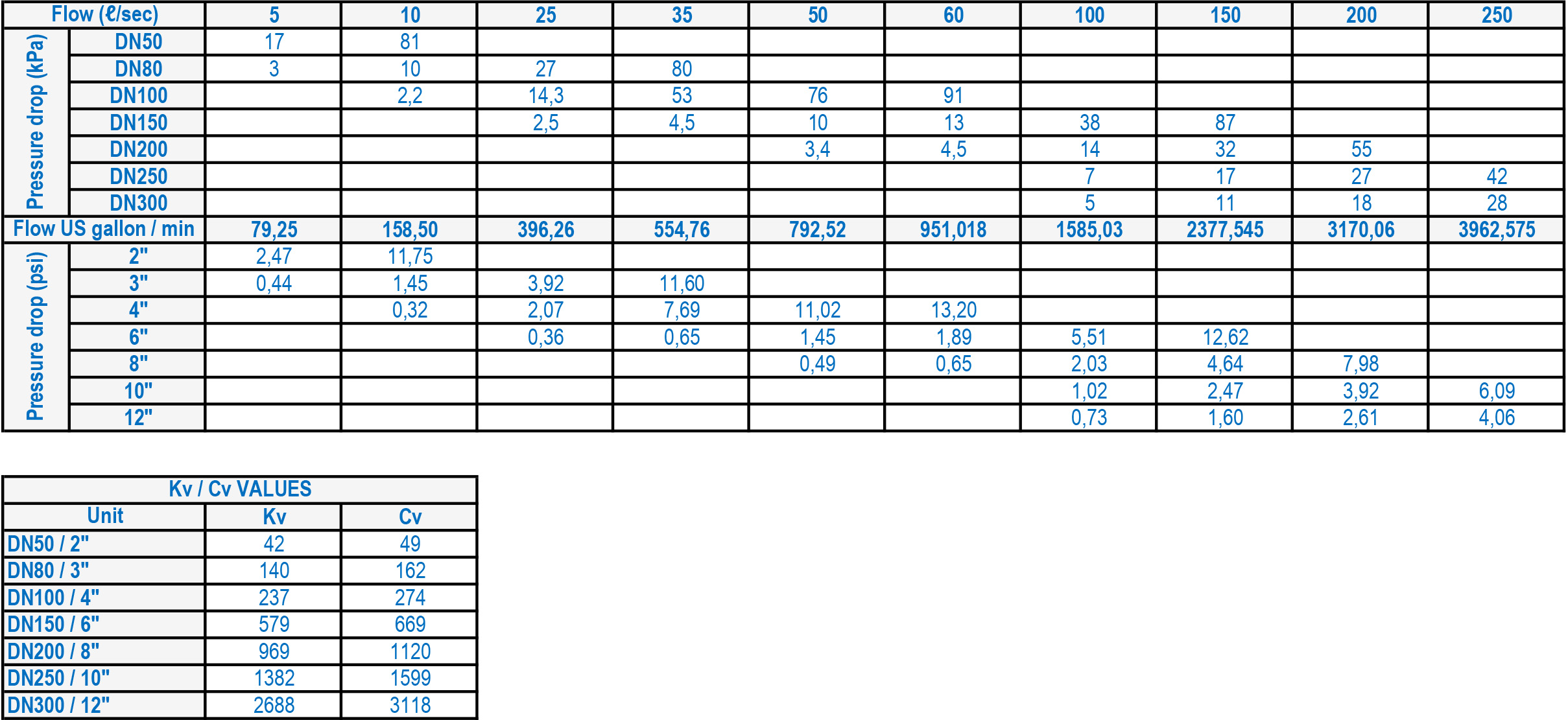

FLOW RATES

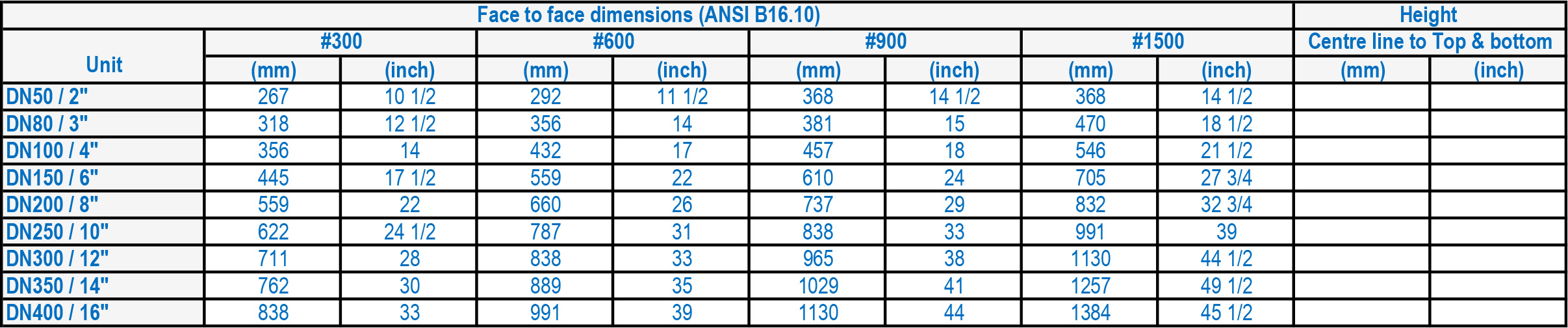

DIMENSIONS

DESIGN AND MANUFACTURING STANDARDS

The HYDROMINE™ LFC_1B nitrogen acting relief valve has been designed in accordance with various international standards as set out below:

ASME Boilers and pressure vessels design code

ANSI B16.10 API 598

ANSI B16.34 ANSI B16.37

ANSI B16.5 ANSI N278.1

Available sizes: DN50 / 2" to DN400 / 16"

Face to face dimensions to ANSI B16.10

Pressure rating: up to 25MPa / 3 626 psi

Available end connections: ANSI B16.5, BS4504, BS10, AS/NZS 4331.1 (ISO 7005-1) DIN, All makes of grooved or ring joint couplings, HYDROMINE™ HMP U-Coupling, HYDROMINE™ HMP -TE tapered couplings and other as per clients requirement.

DOWNLOADS